CNC Hydraulic Profile Bending Machine

CNC Hydraulic Profile Bending Machine

INQUIRY

Description

Specification

W24S Series Profile Bending Machine/Section Bending Machine

Machine introduction:

This profile bending machine is a high efficiency equipment used to bend all kinds of profiles such as angle,channel,I-beam,flat bar,square tube,tube,pipe and so on.Once feeding then finish bending and pre-bending.It is widely in petrol, chemical, shipyard, metal working and machine manufacturing industries.

Features:

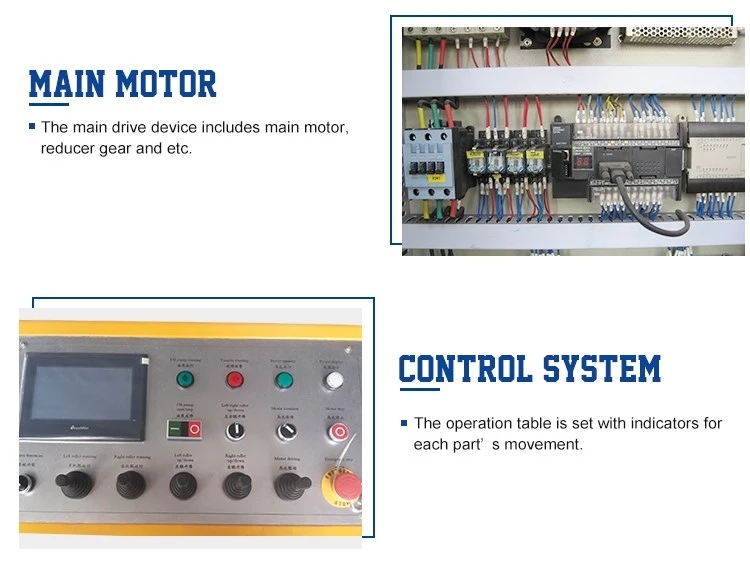

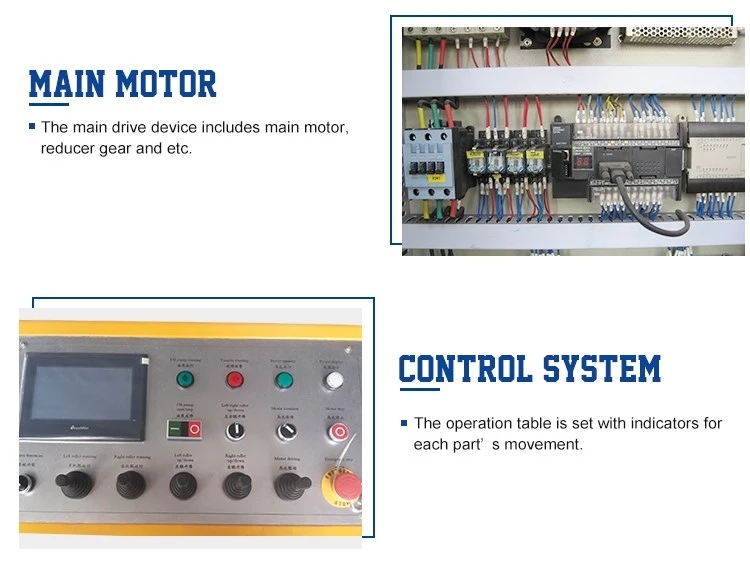

1.Full hydraulic transmission,electrical centralize control,digital read out,once feeding without return to finish bending and pre-bending and other process.

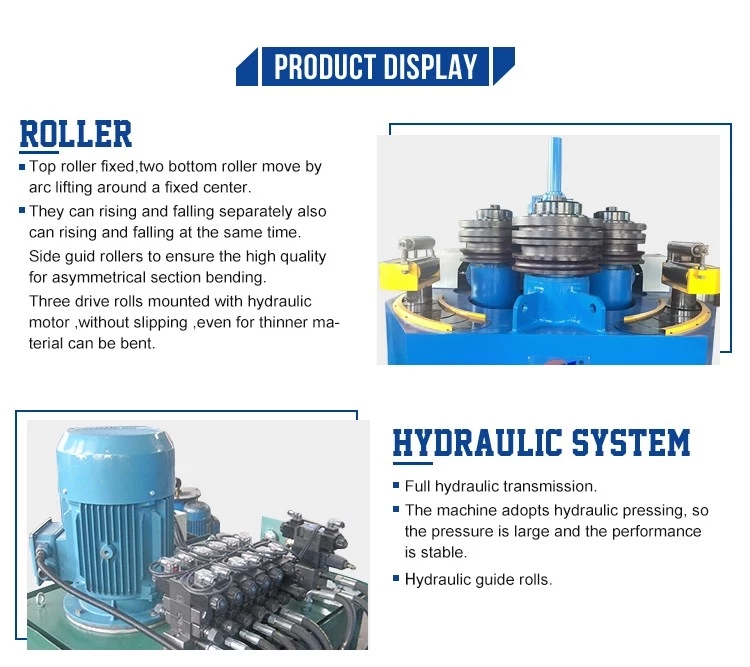

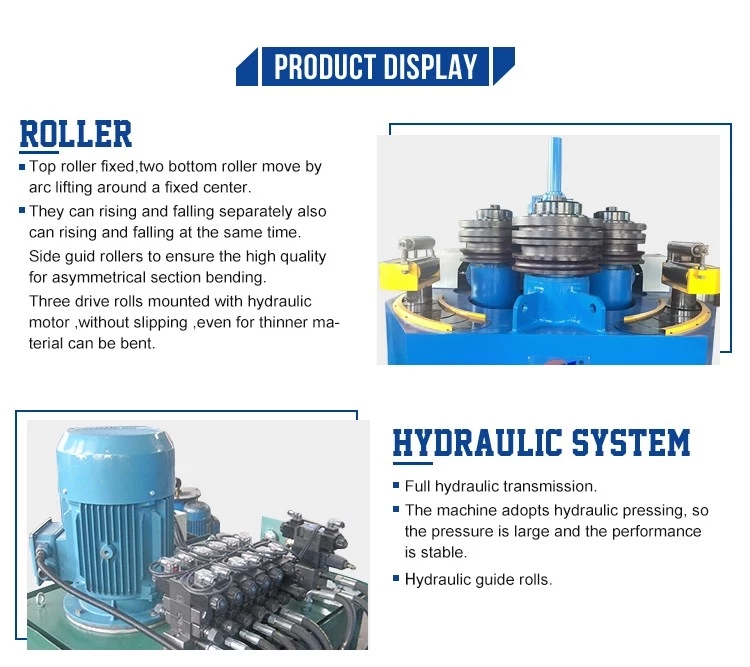

2.Top roller fixed,two bottom roller move by arc lifting around a fixed center.they can rising and falling separately also can rising and falling at the same time.

3.Three drive rolls mounted with hydraulic motor,without slipping,even for thinner material can be bent.

4.Side guide rollers to ensure the high quality for asymmetrical section bending.

5.Full function,replace the mold,various profile can be bent.

6.Vertical and horizontal optional.

7.NC or CNC can optional by customer.

8.CE certificate

Include:

1 set of standard hardened and ground rolls (special steel)

All rolls Planetary/Gear – Hydro motor Driven

Side supports are suitable for angle iron bending leg in -Leg Out

Portable control panel

Horizontal and Vertical optional

Body constructed of stress-relieved steel

Overload protection on hydraulic and electrical systems

Bottom rolls hydraulically adjustable with digital readout

Full function,various profile can be bent by replace the mold

NC or CNC can optional by customer

2D CNC Profile Bending Machine

Main Spec

Technical data |

W24S(WY24-) |

| 6 |

16 |

30 |

45 |

75 |

100 |

| Max. Bending resistant modulus |

6 |

16 |

30 |

45 |

75 |

100 |

| Bending speed |

6 |

5 |

| Yield limit |

S=245Mpa |

| Angle,inner bending |

Max.section size |

40x5 |

70x8 |

80x8 |

90x10 |

100x10 |

120x12 |

| Angle,outer bending |

Max.section size |

50x5 |

80x8 |

90x10 |

100 |

120x12 |

140x16 |

Channel,

Outer bending |

Channel size |

8 |

12 |

16 |

20 |

25 |

28 |

| Channel,inner bending |

Channel size |

8 |

12 |

16 |

20 |

25 |

28 |

| Plate,flat bending |

Max. Section size |

100x18 |

150x25 |

180x25 |

200x30 |

220x40 |

250x40 |

Plate,

vertical bending |

Max. Section Dia. |

50x12 |

75x16 |

90x20 |

100x25 |

110x40 |

120x40 |

| Tube bending |

Max. Section size |

42x4 |

76x4.5 |

89x5 |

89x8 |

114x5 |

159x5 |

| Rod bending |

Max. Section size |

38 |

52 |

62 |

75 |

85 |

90 |

| Square bending |

Max. Section size |

45x3 |

60x4 |

70x4 |

980x6 |

900x8 |

100x10 |

| Technical data |

W24S(WY24-) |

| 140 |

180 |

260 |

320 |

400 |

500 |

| Max. Bending resistant modulus |

140 |

180 |

260 |

320 |

400 |

500 |

| Bending speed |

4 |

| Yield limit |

S=245Mpa |

| Angle, inner bending |

Max.section size |

140x16 |

150x16 |

160x16 |

180x14 |

200x18 |

200x20 |

| Angle, outer bending |

Max.section size |

150x16 |

160x16 |

180x14 |

200x18 |

200x24 |

250x25 |

| Channel,Outer bending |

Channel size |

30 |

32 |

36 |

40 |

45 |

50 |

| Channel,inner bending |

Channel size |

30 |

32 |

36 |

40 |

45 |

50 |

Plate,

flat bending |

Max. Section size |

280x50 |

300x50 |

330x50 |

360x60 |

400x75 |

500x76 |

| Plate,vertical bending |

Max. Section Dia. |

150x40 |

180x30 |

190x40 |

190x50 |

200x50 |

200x60 |

| Tube bending |

Max. Section size |

168x6 |

168x8 |

219x8 |

245x8 |

273x8 |

323x10 |

| Rod bending |

Max. Section size |

100 |

110 |

120 |

135 |

150 |

160 |

| Square bending |

Max. Section size |

125x10 |

140x10 |

150x10 |

165x10 |

180x12 |

200x12 |